Concrete septic tanks are used in most septic systems. One of the main advantages they have over fiberglass and plastic septic tanks is that they are less prone to “floating” due to the fact they are much heavier.

Concrete septic tanks do have one main drawback. Because they are much heavier than other types of septic tanks, they require heavy equipment to move. Both fiberglass and polyethylene septic tanks can easily be moved by a labor crew, whereas concrete septic tanks typically require a truck equipped with a crane and boom. As as result, fiberglass tanks are often used in areas inaccessible to concrete septic tank delivery trucks.

The long-term performance of the septic tank will depend on its structural integrity. For concrete septic tanks, structural integrity is dependent on the method of construction, the placement of the reinforcing steel, and the composition of the concrete mix. For maximum structural integrity, the walls and bottom of the tank should be poured monolithically. Where the walls and the bottom are poured monolithically, the top should be cast in place with the reinforcing steel from the walls extending into the top slab. In some cases, a water seal is placed between the wall and the top.

Watertight concrete septic tanks are a necessity for the protection of the environment and for the operation of the system. Each tank should be tested for water-tightness and structural integrity by filling the tank with water before and after installation. Hydrostatic testing is conducted at the factory by filling the tank with water and letting it stand for 24 hours. If no water loss is observed after 24 hours, the tank is acceptable. Because some water absorption may occur with concrete tanks, the tank should be refilled and allowed to stand for an additional 24 hours. If the water loss after the second 24-hour period is greater than 1 gallon the tank should be rejected. It is important that the above procedure be repeated once the tank is installed.

The size of the concrete septic tank will depend on a number of factors such number of bathrooms in the house, local regulations etc. The minimum size is typically 1,000 gallons. It is typically about 9 feet long, 4-5 feet wide and 5 feet tall.

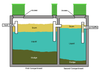

Concrete Septic tanks may have one or two compartments. Two-compartment tanks do a better job of settling solids and are required in some areas for new installations. Tees or baffles at the tank’s inlet pipe slow the incoming wastes and reduce disturbance of the settled sludge. A tee or baffle at the outlet keeps the solids or scum in the tank. All tanks should have accessible covers for checking the condition of the baffles and for pumping both compartments. Here is a picture of a 2 compartment septic tank.

As you may know from researching this topic, failing septic systems are a major financial and environmental problem in this country. Expensive septic repairs can often run from $5,000 to $20,000 or more and a large number of systems are failing throughout the country. For news stories related to failing septic systems and tightening regulations you can go to:https://the-laundry-alternative.myshopify.com/blogs/blog/concrete-septic-tank

You also can’t sell your home if it has a failing system. For more information on how to properly maintain your septic system, go to:https://the-laundry-alternative.myshopify.com/blogs/news/septic-system-maintenance